Axial Bearing Damage

On the other side of the coin some facilities use water that contains contaminates that can build up on the coolant jacket that can restrict or even completely clog the water flow. Contaminates in the coolant fluid can also deposit scale on the coolant jacket. This reduces the ability of the jacket to remove heat from the motor windings. Scale build up or restrictions in the coolant jacket can result in a motor failure from overheating. At HST we always remove and clean the coolant jacket. With every spindle rebuild all components are thoroughly cleaned and inspected. They must pass our stringent QA process. But sometimes they don’t. What then?

Most of the damage we see on axial bearings is the result of contamination in the air supply or internal coolant leakage. But axial bearing damage can also result from contamination migrating past the front labyrinth seal.

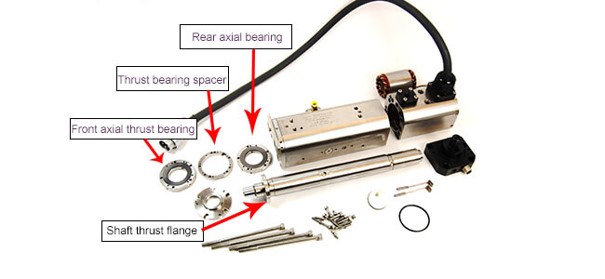

Axial bearings typically are located toward the front of the spindle. They are referred to as the front thrust bearing, rear thrust bearing and the shaft thrust flange.

Axial bearing prevent the spindle shaft from moving in and out of the spindle.

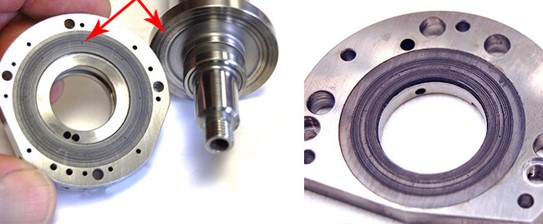

The front axial bearings are often damaged from contamination entering the spindle through the labyrinth seal. If the spindle is not properly setup or maintained, cutting slurry can penetrate the seal and work its way between the front axial bearing and the shaft thrust flange severely damaging both surfaces.

Contamination from cutting slurry wore deep striations on both the shaft thrust flange and the front axial bearing.

Right Photo: This Disco front axial bearing is badly damaged from cutting slurry contamination.

Liquid contamination plugged the journal jets and then the air pressure blew the graphite bearing out of the rear thrust housing